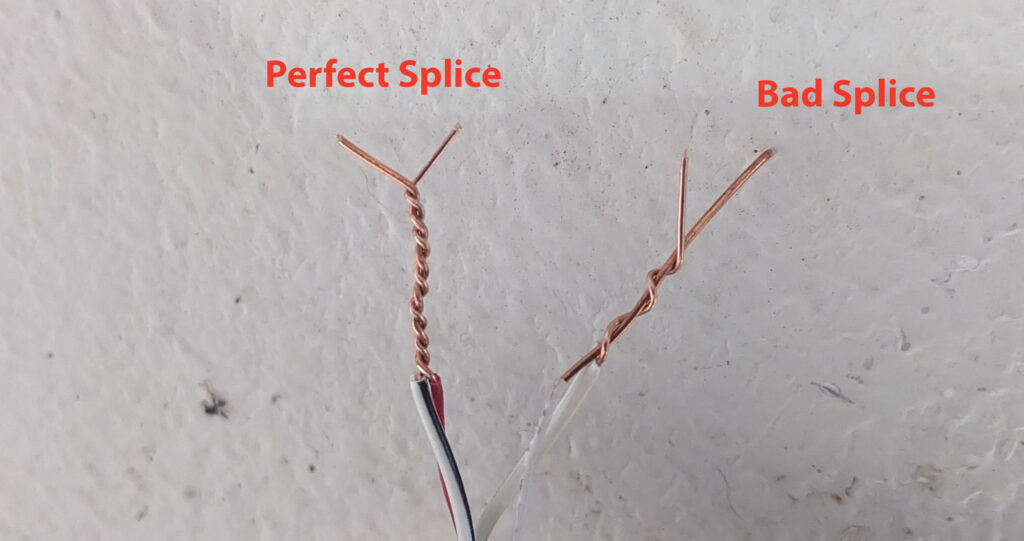

The most common reason for a bad splice is wires that were not twisted together the right way. I see this all the time out in the field.

There are two things that lots of installer get wrong when they twist two wires together (especially if they are different thickness).

First, they don’t twist the wire enough times. One or two turns is not going to hold up long term. I always twist the wires together a minimum of seven turns.

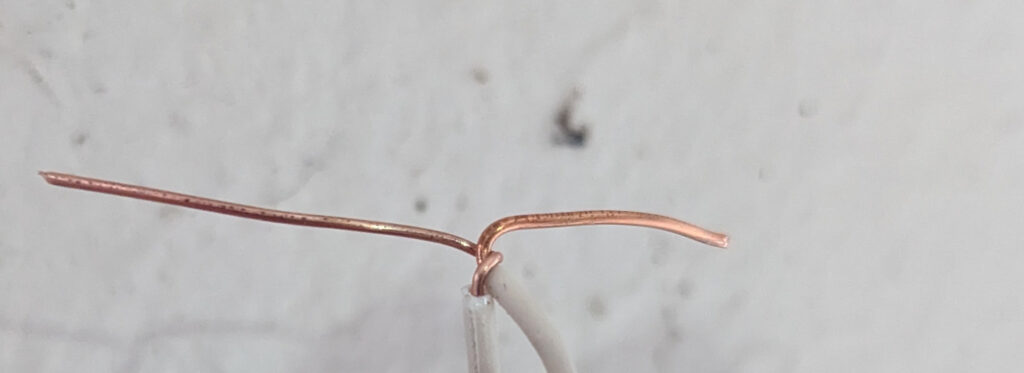

The second common error is the way that the wires are twisted. If you leave one of the wires straight and just wrap the other one around it (see above), the connection may go bad a few years down the road. Instead, start your splice by bending the wires around each other at a 90 degree angle.

From there, twist the wires at least seven times before you finish with electrical tape.

If you don’t do a good job on your splice, you will end up with a low quality connection that will come and go like the one in this video.